Anthracite Binder

Related Content:

Binder For Air-Dried Briquette Of Anthracite

Product Specification

Executive Standard: Q/HJSY 001-2022

Binder Technical Specification | |

Item | Value |

Appearance | Fluid powder |

Fineness: (-250μm) (%) | ≥90.0 |

Moisture Content (%) | ≤12.0 |

pH | 7.0-9.0 |

Bulk Density (g/L) | 1000±300 |

Viscosity (mPa·s) | ≥5 |

The air dried briquette anthracite binder is a special adhesive for anthracite powder, and the green balls can be placed directly to dry without going through the drying process.

This innovative technology has been widely adopted by the briquette industry to recover carbon resources, improve energy utilization efficiency, reduce energy consumption, and save production costs.

In addition, this type of adhesive is better than traditional inorganic adhesives because they are free from drying, have strong adhesion, high forming rate, no corrosion to equipment, no increase in ash content, no decrease in calorific value, and no flame retardancy. The pellets produced by using anthracite drying-free binder have uniform particle size, good air permeability, and good cold strength, which meet the requirements of industrial briquettes, civil briquettes, barbecue charcoal, and heating charcoal. Through this process, it is one of the effective ways to solve problems such as the effective utilization of pulverized coal and the insufficient amount of lump coal required for industrial production, the reduction of environmental pollution, and the reduction of energy consumption.

Product Characteristics

Quick Curing:

Green briquettes can be cured quickly without an oven. They simply need to be stored at room temperature for 12 hours before being bagged and shipped.

Ease of Use:

Cold press the mixture of binder and material, add water and stir evenly, the process is simple.

High Binding Strength:

Because of its ability to form a network structure inside the material, briquettes have high forming strength. It can withstand high temperature of 850°C for 1 hour, the forming strength can surpass 80 kg , and the overall strength exceeds 55kg.

Cost Reduction:

No need to invest in oven and drying process, thus reducing the overall cost.

High Forming Rate:

The briquette forming rate is high, which can reach more than 98% and 2m-drop integrity (wet briquette).

The product is energy-saving and environmentally friendly.

Product Maintenance

Get Free Sample:

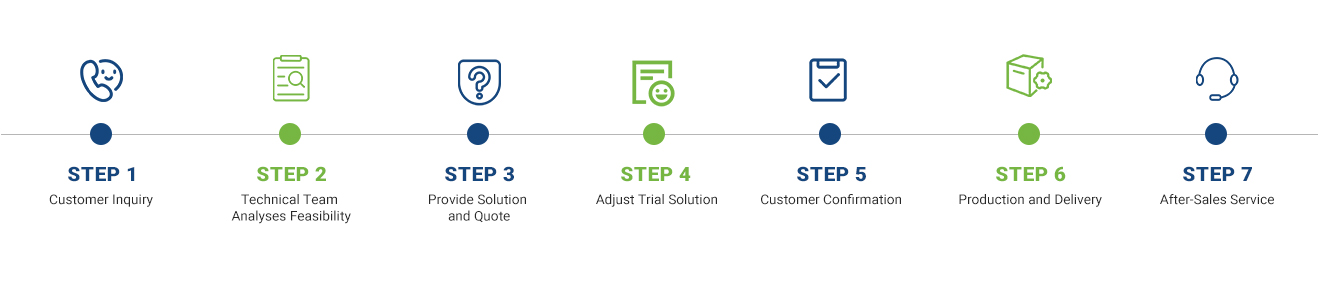

Service Process

Our Services

We specialize in customizing comprehensive solutions tailored to our clients' unique requirements, encompassing production line design, equipment upgrades, and product parameter adjustments based on trial outcomes, ensuring performance and feasibility alignment. Our team comprises seasoned experts with profound theoretical knowledge and practical engineering experience in binder engineering R&D, design, manufacturing and technical support. We offer a comprehensive suite of services, including technical consultation, scheme design, product fabrication, equipment sourcing, installation & commissioning, binder supply, production operation, and after-sales support. Furthermore, we provide turnkey EPC (Engineering, Procurement, Construction) services or phased EPC solutions, tailored to meet our clients' requirement.

Our Factory

Jianjie Group invested 20 million USD to build a new composite material production base and automated production line in Dazhou, Sichuan Province.It covers an area of more than 13,300 square meters and has nearly two hundred employees. We focus on binder industry for 20 years and our products are exported to more than 20 Countries.With an annual production capacity of up to 300,000 MT, the production scale is among the top in the same industry in China.Our main products are iron ore organic binder, RHF dezincification deusting ash binder, dedusting ash briquettes binder,metallurgical furnace binder, drilling fluid filter loss reduction agent, coke powder binder,air dried briquettes binder, carbon additive binder,Pre-gelatinized maize starch etc.

FAQ

Products

Our products have strong viscosity, high forming rate & anti-calcium properties, and are also environmentally friendly & cost-effective.

Yes, we can. Our binder can increase strength and viscosity. Customized products are also available according to your requirements.

One year.

Transportation

It normally takes 3-5 working days for production.It usually takes 30-45 days by sea to your port .

Our term of delivery are EXW, FOB , CFR and CIF.

25KG per plastic woven bag or 1000KG per jumbo bag.