Iron ore accounts for roughly 98% of global iron use in steel production. With the rising demand for efficient, low-emission steel, understanding the different types of iron ore and their behavior during التكوير is critical. This article explores major iron ores, their roles in steelmaking, pelletizing challenges, and how Jianjie’s binders optimize performance.

Types of Iron Ore and Their Characteristics

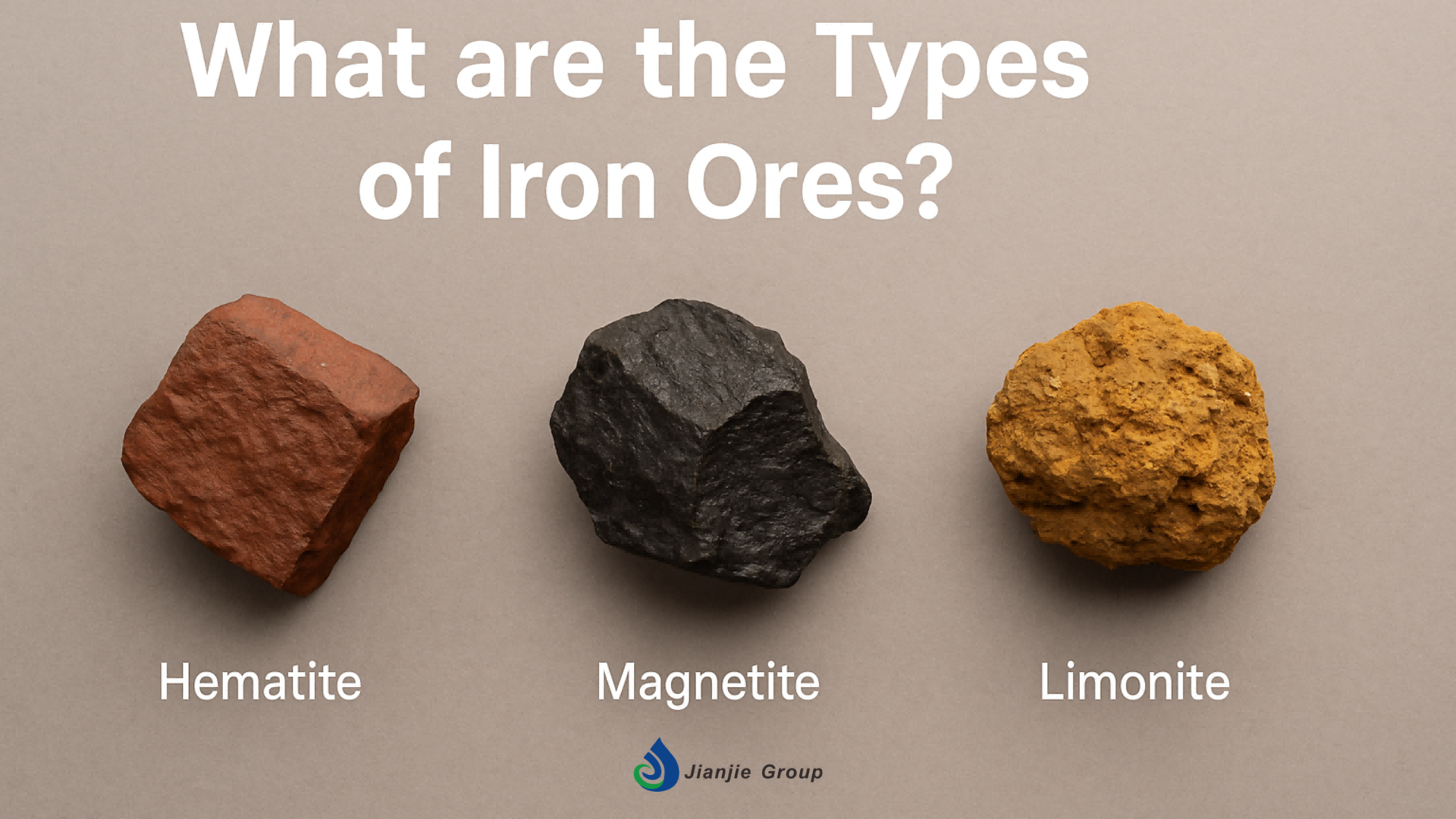

Hematite (Fe₂O₃)

A reddish-brown to black iron oxide, Fe₂O₃, one of the most important iron ores due to high iron content (~70%)

- Iron Content: ~70% Fe

- Properties & Use: Found in forms such as specular, micaceous, and earthy hematite. It’s easy to grind and pelletize, making it ideal for BF sinter feed.

Magnetite (Fe₃O₄)

A black, opaque iron oxide mineral (Fe₃O₄), strongly magnetic.

- Iron Content: Up to 72.4% (highest among ores)

- Properties & Use: Contains both Fe²⁺ and Fe³⁺. Requires beneficiation due to fine particle size. Commonly used in both BF and DRI applications.

Limonite (FeO(OH))

A common hydrated iron oxide-hydroxide (α-FeO(OH)), recognized as the most widespread iron oxide after hematite

- Iron Content: Varies (~58–63%)

- Properties & Use: Formed through oxidation of iron-rich minerals.

Siderite (FeCO₃)

Iron carbonate mineral found in sedimentary rocks and hydrothermal veins.

- Iron Content: ~48% Fe

- Properties & Use: Contains no sulfur or phosphorus. Less commonly used due to its carbonate nature, but sometimes blended in low-impurity pellet feed.

Taconite

A low-grade mix of hematite/magnetite, needing beneficiation before utilizing.

- Iron Content: ~25–30% before processing.

- Properties & Use: Requires extensive beneficiation. Widely pelletized in the U.S. Great for BF use post-processing.

Pyrite (FeS₂)

One of the most common sulfide mineral. Iron sulfide mineral (FeS₂), with a brassy yellow metallic luster—commonly called “fool’s gold”

- Iron Content: ~46%

- Properties & Use: High sulfur content makes it unsuitable for steelmaking. Mostly used in sulfuric acid production or roasted as a reductant.

Iron Ore in Steel Production

Iron ore is used primarily in two steelmaking routes:

Blast Furnace (BF): Uses sinter and pellets from high-grade ores (e.g., hematite).

Direct Reduced Iron (DRI): Prefers magnetite-based pellets, especially for hydrogen-based green steel.

تكوير خام الحديد

Disk Granulator is Pelletizing Pellets

In order to be used in steel production, iron ore are first grounded into properly sized fines and granules, and then pelletized using disk granulator and indurated in machines like rotary kiln. They will be formed into round balls in uniform size in order to reach optimized mechanical and physical strength.

Iron ore type significantly affects pelletizing performance and binder requirements. Key ore properties—mineralogy, particle size, moisture, iron content, and gangue chemistry—influence the success of pelletizing at every stage:

- Green ball formation

- Drying

- Induration (firing)

- Reduction

Different ores require different binder strategies. The right binder improves green and fired pellet strength, ensures stable drying, and helps deliver high-quality pellets for steelmaking. Ultimately, metallurgical performance defines the value of a pellet.

What Makes a Good Binder for Iron Ore Pellets?

Iron ore pelelts

A good pellet binder should:

- Spread evenly through the ore

- Help form strong “green” (wet) pellets (good mechanical and metallurgical performance)

- Keep pellets intact during drying and heating

- Not add unwanted impurities like silica or alumina

Important Types of Binders:

Inorganic Binder (Bentonite clay): Common and cost-effective, builds strength in green and fired pellets. But adds silica/alumina impurities and lowers iron content

Organic binders (like starch, humic acid, or polymers): Improve green pellet strength, burn off cleanly, and preserve iron purity. But often lack strength after firing unless combined with inorganic additives

المجلدات المركبة: A combination of inorganic binder and organic binder—giving strength and cleaner final pellets

Binder Impact on Iron Ore Grade

The properties of binder will pose direct impact on iron ore grade. For example, in pelletizing of iron ore, every 1 wt% of bentonite added can reduce Fe grade in finished pellets by ~0.6%, or about 7 kg per ton of ore.

Reducing bentonite use by 1 wt% can increase Fe grade by the same amount.

How the Iron Ore Pellet Process Work?

Balling (Pelletizing – Making Green Pellets):

In disc or drum granulators, add water into the raw material and mix binder to form spherical pellets.

Drying & Heating (Induration):

As green pellets heat up, water vapor can cause cracks if binder isn’t strong.

High gangue (non-iron) content in ore can cause pellets to stick together or melt improperly.

Binders help control cracking and maintain the structure during heating and cooling

Jianjie Binder for Iron Ore Pellets

Jianjie Group offers advanced organic binder solutions that help:

- Reduce bentonite use or eliminate it altogether

- Improve Cold Crushing Strength (CCS)

- Boost pellet productivity

- Raise iron content by avoiding silica/alumina contamination

These binders are tailored to match the unique needs of different iron ore types—offering both environmental and economic advantages for steel plants.

Looking For Pelletizing Solutions?

Choosing the right binder isn’t just about sticking the powder together—it’s about adapting to the unique behavior of each iron ore type. Jianjie’s pellet binder solutions are designed to improve performance, reduce impurity, and support greener, more efficient steel production.

Contact us now if you need help on improving iron ore pellet quality.

Iron Ore, Pelletizing & Binder – FAQ

1. Why is iron ore pelletizing important?

Pelletizing transforms fine iron ore powder into uniform pellets, making it easier to:

- Handle and transport.

- Use in blast furnaces or DRI (Direct Reduced Iron) processes.

- Improve furnace efficiency and reduce waste.

2. What is a binder in iron ore pelletizing?

A binder is a substance added to help iron ore particles stick together during pellet formation. It:

- Increases green (wet) pellet strength.

- Improves drying and induration performance.

- Enhances Cold Crushing Strength (CCS) of finished pellets.

3. Can Jianjie Binder work with all iron ore types?

Yes. Jianjie offers customized binder formulations that adapt to various ore types (hematite, magnetite, goethite, etc.), improving:

- Iron ore pellet formation

- Drying and firing behavior

- Final pellet strength and quality