Coal & Green Energy Briquetting Solution for Coal, Coke Fines, & Biocharcoal

Coal fines, coke powder, and biocharcoal are valuable energy materials that often exist in fine or dusty forms, making them difficult to handle, transport, and reuse efficiently.

Jianjie’s cold briquetting technology for coal and green energy briquettes provides an effective way to transform these dispersed particles into dense, uniform briquettes — improving combustion efficiency, reducing waste, and supporting the transition toward cleaner and more sustainable energy use.

The Challenge

Key Challenges in Dealing with Coal Briquettes

Producing strong, clean-burning briquettes from fine carbon materials (biomass briquettes, coal briquettes) is technically demanding — issues like moisture control, low binding strength, and inconsistent combustion properties often affect product quality and efficiency.

Coal, coke fines, and carbon powders are often extremely fine and difficult to compact, leading to weak briquettes and high dust loss during production and handling.

High ash content or impurities reduce the calorific value of the coal briquettes and create more residue during combustion. This directly affects furnace efficiency and increases cleanup or maintenance costs.

High ash content or impurities reduce the calorific value of the coal briquettes and create more residue during combustion. This directly affects furnace efficiency and increases cleanup or maintenance costs.

Different coal grades vary in volatile matter, fixed carbon, ash content, and reactivity. These variations significantly influence coal and coke briquette strength, burn efficiency, and binder compatibility, making process optimization challenging.

Stricter regulations require cleaner combustion with lower SOx, NOx, and particulate emissions. Plants must adjust binder systems and process parameters to meet environmental standards without sacrificing briquette strength.

Stricter regulations require cleaner combustion with lower SOx, NOx, and particulate emissions. Plants must adjust binder systems and process parameters to meet environmental standards without sacrificing briquette strength.

The Solution

Jianjie Solutions for Your Coal and Coke Briquetting

Jianjie develops specialized binders and provides briquetting solutions for coal briquettes, coke briquettes, and biocharcoal, helping customers achieve stable production, cleaner combustion, and higher economic value.

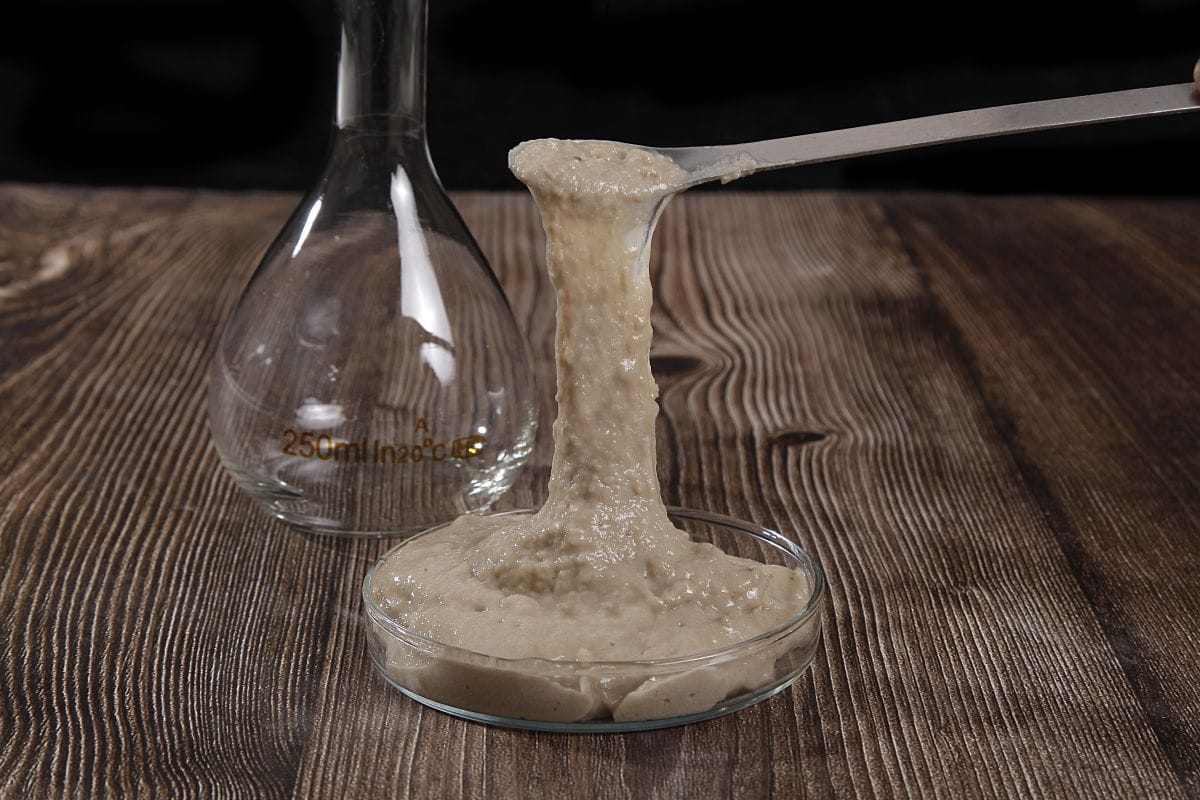

Binder Designed for Ultra-Fine Powders

Jianjie analyzes ultra-fine coal, coke, and biocharcoal powders to understand their particle size, ash content, and reactivity, then recommends the most suitable binder system for stable briquette strength.

Production Process Optimization

Through on-site trials or technical guidance, Jianjie assists clients in controlling moisture, improving feeding stability, and adjusting press parameters—ensuring consistent production even with challenging carbon materials.

Solutions based on Different Coal Grade

Different coal grades behave differently in briquetting. Jianjie provides testing, evaluation, and tailored recommendations to ensure briquettes remain stable and high-performing across diverse volatile, carbon, and ash profiles.

Emission Compliance Support

Jianjie evaluates the client’s combustion process and recommends binder types and briquetting conditions that help reduce emission risks and support compliance with SOx/NOx and particulate regulations.

Coal & Coke Briquette Binder Solutions

In coal and coke briquetting, binder performance directly affects briquette strength, combustion behavior, and handling stability. Jianjie’s coal, coke briquette binders are designed to improve bonding efficiency for coal powder, coke breeze, and biomass-blended materials—supporting stable forming, reduced breakage, and reliable downstream use in energy and metallurgical applications.

Guides & Insights on Coal Briquettes and More

Access practical guides and technical insights on coal and coke briquetting, including material preparation, binder selection, strength optimization, and clean energy utilization. These resources help producers improve briquette quality, process stability, and overall energy efficiency.

Already Have a Briquetting Machine? Looking for Binder Solutions?

Tell us your coal, coke, or biocharcoal type and working conditions. Our engineers will recommend the most suitable briquetting binder for your process.

Have Raw Materials but No Complete Solution?

Share your material type and production goals.

Мы предоставляем complete briquetting solutions, including process design, binder selection, and technical support.