In the global aluminum industry, the issue of red mud, also called bauxite residue, has become one of the most pressing environmental challenges. Every ton of alumina produced by the Bayer process results in 1.5 to 1.8 tons of red mud waste. With worldwide alumina output exceeding 140 million tons annually, this means that more than 200 million tons of red mud are discharged each year.

Traditionally, this highly alkaline waste is stored in large tailing ponds or dams, but these facilities consume huge amounts of land and carry long-term risks of leakage, dam failure, and groundwater pollution. The growing environmental pressure has forced industries to explore waste recycling solutions. Among the most promising is the development of red mud briquettes, which can transform hazardous residue into valuable industrial resources. By combining advanced processing with innovative binder technologies, companies like Jianjie are pioneering efficient ways to close the loop on red mud utilization.

What is Red Mud?

Red mud is the byproduct of alumina production through the Bayer process, in which bauxite ore is digested with caustic soda. During refining, alumina is dissolved, leaving behind an insoluble solid residue known as bauxite residue.

The main characteristics of red mud include:

Composition: High levels of iron oxide (giving it a reddish color), alumina, silica, titanium dioxide, calcium compounds, and residual caustic soda.

Properties: Fine particle size, strong alkalinity (pH 10–13), high moisture content, and difficulty in settling and filtering.

Environmental Risks: Its fine dust easily becomes airborne, while its alkaline leachate can seep into groundwater, creating long-term ecological hazards.

Because of these challenges, red mud is often regarded as one of the most difficult industrial solid wastes to manage effectively.

The Challenges of Red Mud Management

Despite decades of research, red mud continues to pose significant difficulties in waste management:

Storage Limitations

- Vast land areas are required for tailing ponds, putting pressure on surrounding communities.

- Safety concerns over dam stability have been highlighted by several international incidents of red mud leakage.

Environmental Impact

- Alkaline seepage from storage areas can contaminate soil and groundwater.

- Drying red mud generates dust pollution, affecting air quality and public health.

Wasted Resources

- Red mud contains valuable elements such as iron, aluminum, titanium, and rare metals like gallium.

- Without recycling, these materials are effectively lost, despite their economic value.

Complex Physical Properties

- Its fine particle size, high moisture, and strong alkalinity make it unsuitable for direct industrial use without treatment.

- These barriers highlight the urgent need for practical, scalable, and environmentally friendly methods to recycle red mud.

Why Briquetting Red Mud is the Solution

Among the various recycling technologies, cold briquetting has emerged as a particularly attractive approach. Unlike high-temperature sintering or roasting, cold briquetting is energy-efficient, environmentally friendly, and cost-effective.

Key benefits include:

Material Compatibility: Although different from bentonite, red mud’s fine particle size and mineral phases can be modified to achieve binder-like behavior suitable for briquetting. After surface modification, it can be effectively compacted into briquettes for reuse.

Industrial Substitution: Red mud from sintering alumina production contains phases such as calcium silicate and iron oxide, giving it some functional similarity to blast furnace slag, allowing partial substitution in cementitious applications. This makes it suitable for blending with cement, lime, fly ash, and gypsum to form modified mortar materials with strong binding capacity.

Pollution Control: Briquetting immobilizes harmful alkaline components, preventing dust emissions and reducing the leaching of soluble substances.

Energy and Cost Savings: Unlike sintering or calcination, cold briquetting does not require high temperatures, significantly reducing energy consumption and production costs.

This process turns a hazardous residue into a manageable and valuable feedstock for multiple industries.

Industrial Applications of Red Mud Recycling

The potential applications of red mud briquettes extend across several major industrial sectors:

Construction Materials

- Used as an additive in cement production.

- Manufacturing of non-fired bricks, paving blocks, and building boards.

- Development of magnesite waterproof panels and roadbed stabilizers.

Metallurgical Industry

- Red mud can be beneficiated by magnetic separation to recover iron concentrate.

- Briquettes can be used in electric furnaces as fluxing agents, slag conditioners, or iron-bearing additives, reducing reliance on conventional raw materials.

Metal Extraction

- Red mud contains trace amounts of gallium, scandium, and titanium, which are strategically valuable. Although large-scale recovery is still limited, briquetting may facilitate more efficient extraction in future processes.

- Briquetting allows for more efficient recovery and processing of these valuable elements.

Mining Backfill

- Modified red mud has been tested as a filling material for underground mines.

- Its cementitious properties make it an effective and economical aggregate for mine backfilling, reducing the need for natural materials.

These applications illustrate how waste recycling through briquetting can transform bauxite residue into a valuable raw material.

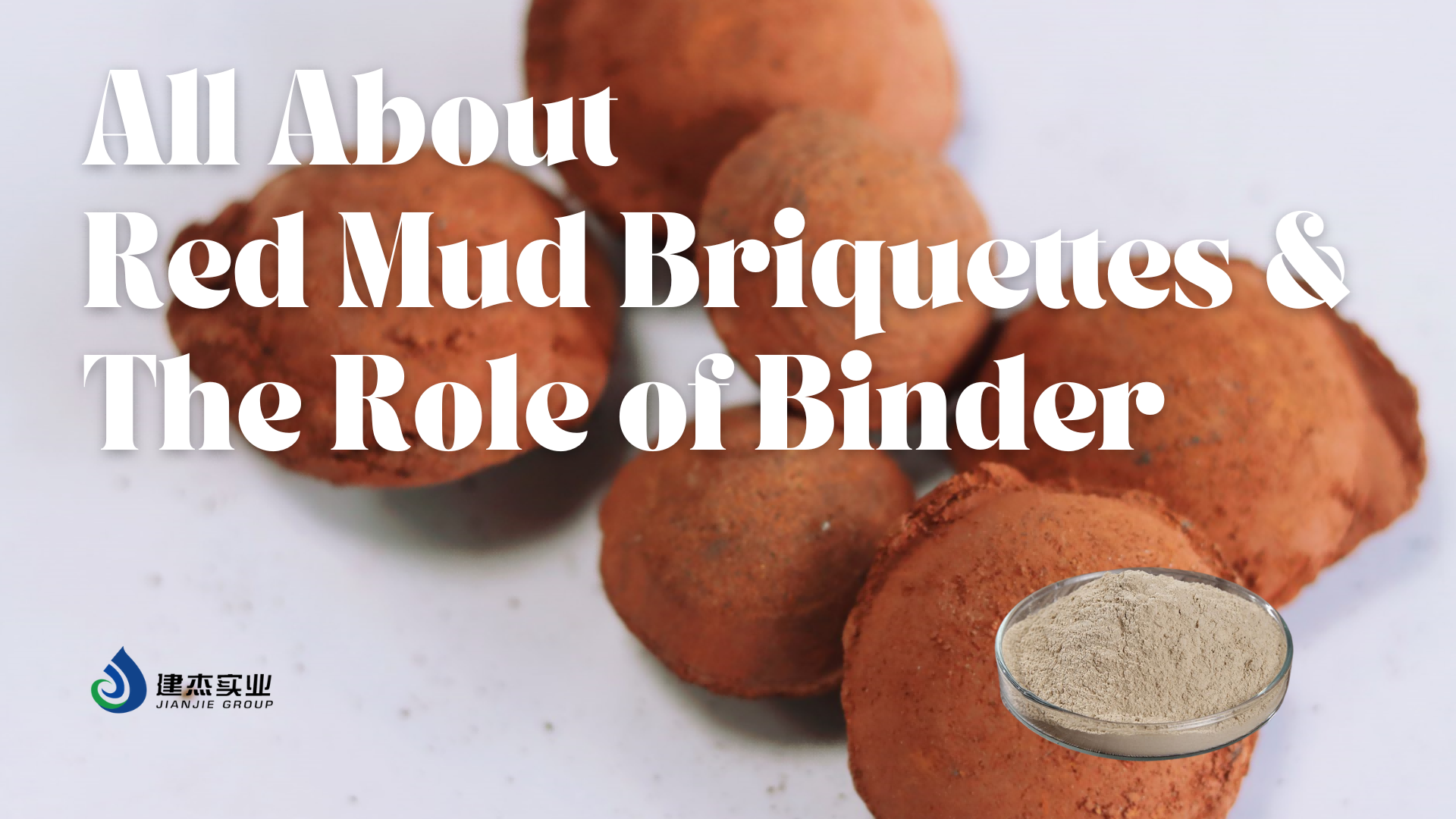

Jianjie Binder: Enhancing the Value of Red Mud Briquettes

Red Mud Briquettes Using Jianjie Specialized Binder

A critical factor in successful red mud briquetting is the binder. Poor binding leads to weak briquettes that crumble during transportation or high-temperature processing. This is where Jianjie binders for red mud briquettes deliver exceptional advantages:

Eco-Friendly Formulation: Free from silica and alumina impurities that could otherwise reduce the grade of iron in metallurgical applications.

High Binding Strength: Ensures uniform particle cohesion, even with fine-grained red mud.

Superior Thermal Resistance: Maintains strength in high-temperature environments such as blast furnaces and rotary kilns.

Low Dosage Requirement: Effective performance at minimal addition levels, lowering costs and maintaining briquette quality.

Adaptability: Tailored formulations for different red mud sources—whether highly alkaline, moisture-rich, or with variable chemical composition.

By improving briquette strength, stability, and processing performance, Jianjie binders make large-scale red mud recycling both technically feasible and economically attractive.

Conclusion

The disposal of red mud (bauxite residue) has long been a global environmental challenge, but cold briquetting now offers a transformative pathway to sustainable waste recycling. Through this process, industries can reduce storage risks, prevent secondary pollution, and recover valuable resources for use in construction, metallurgy, and mining.

As a leader in binder technology, Jianjie provides efficient, eco-friendly, and cost-effective solutions that maximize the value of red mud briquettes. By turning hazardous waste into a resource, Jianjie helps industries achieve both environmental compliance and economic benefit.

Moving forward, greater collaboration among steel, non-ferrous, and cement industries is essential to scale up red mud utilization and accelerate the transition toward a green circular economy. Together, we can transform waste into wealth and build a cleaner, more sustainable industrial future.

If you have any questions about red mud briquetting, feel free to contact us now.

-scaled.jpg)